|

Examples of typical 20 mm cartridges

|

|

Marzocchi

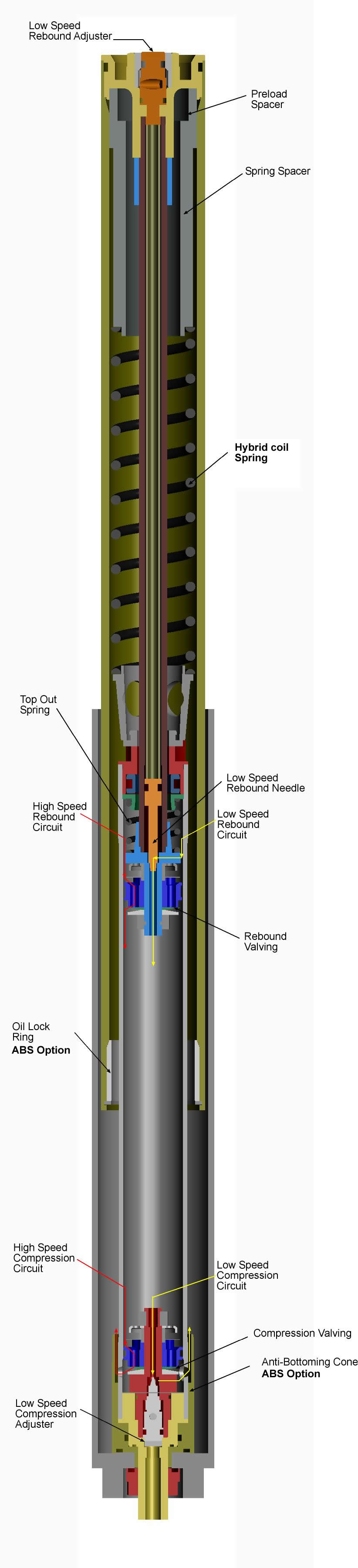

66 RCV 20 mm Cartridge |

Totem

20 mm Cartridge |

| |

|

|

Compression and rebound valves |

Fork rebound caps |

Abs Systems |

Specifications

• Replacement open bath maintenance free speed

sensitive damper assembly, "set it and forget it"

• 20 mm ID damper tube with shimmed 4 port MX style compression

and rebound valving pistons

• Available for 8 inch(200 mm) travel dual forks,single crown 180,170,160,150,140,130,120

mm travel forks

• Upper fork cap adjuster screw with 22 clicks of low speed rebound

• Base valve adjuster screw with 22 clicks of low speed compression

adjustment

• Hydraulic Anti-Bottoming

System (ABS) for end of stroke bottoming resistance

• Speed sensitive multi-stage shimmed compression,

midvalves and rebound valving

• Custom valved and set-up for each rider with printed set-up

charts

• Fork spring and air pressure recommendations help us tune to

to your weight riding style

• Midvalve

kit included with standard cartridge to prevent fork dive, adds

low speed compression without harshness, optional midvalve revalving

shim kit and set-up

charts available

• Optional

revalving kit for compression and rebound pistons, with revalving

set-up charts

• Optional HSB

compression blow-off system for the firmer feel with-out harshness

• Designed to be self-installed

or send it to us for installation if you need us to do the install

• Weight approx. 300 grams

*Self install kit assumes good working knowledge of

internals and service procedures.

Revalve

Kit or Purchase Tools

Download:

20mm Cartridge Kit Revalving and Optional MidValve Procedure (53.2 MB)

Recommended

oil: Golden Spectro

85/150 Cartridge Fork Fluid Recommended

oil: Golden Spectro

85/150 Cartridge Fork Fluid

Background as to why open

bath and not a sealed damper as an upgrade

Since 1994 when

Suzuki introduced the twin chamber forks to the general public and by

1997 most the

high end MX forks replaced open bath dampers with twin chamber dampers.

These dampers are much more complicated than today's

so called

sealed bladder dampers. The longer travel and larger diameters forced

them to

create a pressurized upper chamber(rod displacement pressure spring

IFP reservoir)

that created force on the damper oil in order to prevent cavitation

at the

midvalve. The midvalve(back side of the rebound piston) had become the

dominate

control of damping on longer travel forks because metering the rod displacement

thru the base valve became too crude and harsh at larger shaft displacements.

The current MTB bladder dampers are using the rod displacement to control

damping

with base valves (on top but still referred to as the base valve) to

meter and

control lock out with a high flow piston system and threshold damping

created

by a rim loaded shim preloaded with a spring referred to as a high speed

adjuster. This simple damping design creates a large amount of resistance

to

open the shims, but because of this it acts like a on/off light switch

and creates

a harsh feeling until it blows off. Because the harshness is undesirable,

the adjuster

is generally run all the way out to relieve this harshness, resulting

in very little

damping in the system.

The Push H97 replaces the Trail/Lock part of this circuit

and simplifies the base valve to just a high speed threshold poppet

valve and a

low speed adjuster needle. It does not add a midvalve or replace the

rebound

piston system. The bladder design is still used to capture the displaced

oil,

but is still not pressurized to prevent cavitation. The bladder design

requires

that the damper rod be sealed, in fact this seal/seals has become the

weak link

and still don’t prevent air ingestion into to damper oil, thus

rendering the damper

useless until re bleed. The H97 also suffers from too much threshold

as it also

creates a very harsh feel and most riders have to run very little high

speed

preload to reduce the harshness resulting in very little to no damping

contribution. This results in more fork dive and reduced bottoming resistance

requiring over springing or adding too much progression to the spring

leg.

The twin chamber forks are not actually sealed and contained

stanchion oil for lubrication and hydraulic bottom out. They are also

self

bleeding and ingest small amounts of stanchion oil thru the damper rod

lip seal

and the oil volume in the damper is reset by the ifp bleed off seal

release

during full stroke compressions. This helps prevent accumulated air

ingestion

from becoming an issue. This same type of self bleeding is also accomplished

by

open bath systems in a very simple way by not completely sealing the

damper oil

from the stanchion oil and allowing air to rise thru the rod bushing

during use,

yes small amounts of air bubbles are trapped in the damper fluid causing

a very

slight emulsion but with today's hydraulic fluids the foaming is almost

eliminated.

This is easily account for in the valving. The air over oil creates

a pressure

on the oil to prevent cavitation and further push out or shrink the

air bubbles

to insignificant size thus creating a very consistent and simple damping

system

that’s self bleeding. This pressure is also used to add ramp up

to the fork resulting

in less tokens in the air side for a more linear midstroke air spring.

The

pressure springs also add to the initial spring rate and preload of

the initial

feel of the fork reducing the suppleness of the fork. MX bikes are much

heavier

so this is not as noticeable. The new Grip and Rockshox RC dampers are

using the

pressure spring system to replace the bladder design but are battling

with spring rates and

preload to create a soft initial feel while still trying to reduce cavitation.

|