Why can't I tune my stock suspension to work!

|

Most of today's suspension products have built in pedal platform or provide trail and or lock-out features which are very effective for pedaling and fork dive but are interfering with the descending capabilities of the suspension. Riders are finding their suspension too firm and harsh on high speed bumps like ledge, rocks and roots. They are then forced to set the damper to open and soften all the compression settings to almost all the way out. This creates the illusion in the parking lot that it feels soft but on the trail it is still harsh with a lot of fork dive and now it bottoms. So the band-aid fix is to add volume spacers and now it does not bottom but the fork dive is still there. They try to add back some compression to find a happy medium between fork dive and small bump compliance. Often the next step will be to reduce the air pressure to soften the initial stroke and find the fork harsh now on repetitive bumps because it is packing up, not because the rebound is too slow but because the sag is too much and not enough spring rate to support their rider weight. All these attempts are essentially creating a no compression damper that requires extreme progression in the air spring to prevent bottoming, as I said it becomes the final compromise but it is far from ideal. Harshness on high speed bumps is still there because the damper internals still are limiting the flow of oil thru the restrictive pedal circuits or the stiff threshold of the pedal platform systems. Deep in the stroke the air spring is also ramping up to quickly to absorb square edged high speed rocks and roots and when even bigger hits are encountered the excessive spring rate caused by the progression rebounds back uncontrolled, using a slower rebound setting that works at the bottom of the stroke now causes packing at the top. As you can see this becomes a vicious cycle where trying to fix one issue leads to another. What this all means is that you need to tune your damper for high speed descents and this requires proper damping internals tuned to handle fork dive and provide midstroke support while still feeling plush over small bumps. This proper damping in the beginning of the stroke, along with proper sag, will prevent blowing through the stroke and provide the proper bottoming resistance. This can all be accomplished with a more linear spring rate with a very minimal ramp-up at the end of stroke. |

How Avalanche Suspension Can help!

|

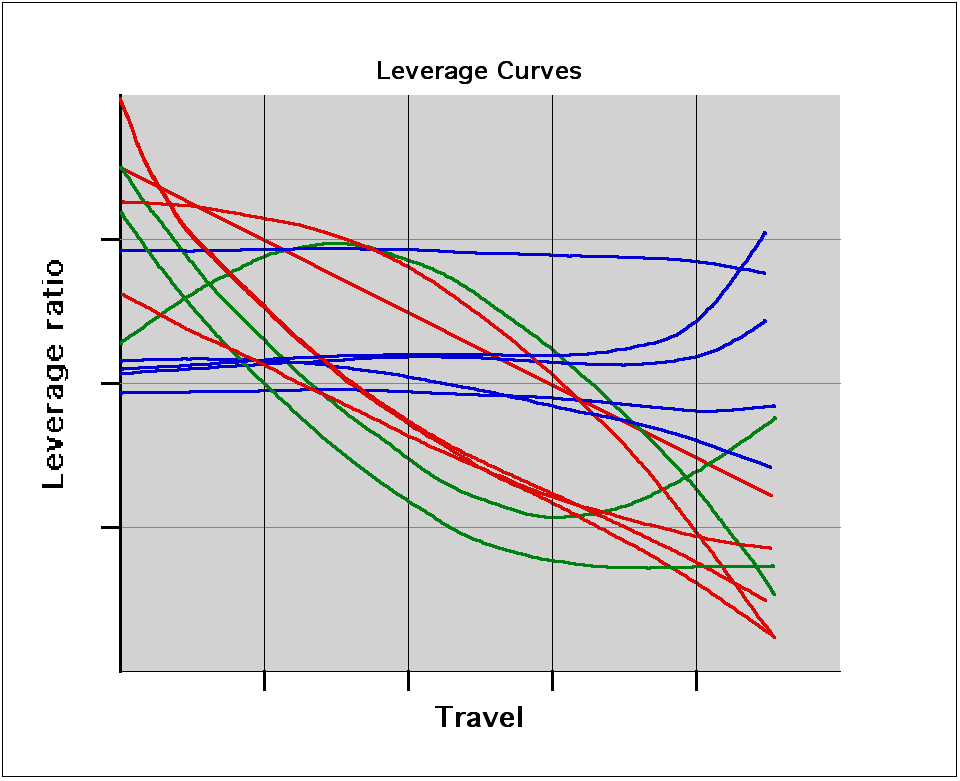

Do you ever wonder if you have the right suspension components on your bike, or are you looking to upgrade them and don't know what to buy or do with them? Let us help, give us a call or e-mail and we will help you sort out your problems and set you in the right direction for the best possible set-up you can get! The goal with all suspension set-ups is to create the most linear spring rate as possible. Coil springs naturally produce a linear rate but air springs are progressive and need mechanisms to fix this, they use an internal trick called a negative spring to help compensate for the topped-out initial feel by pulling down on the first third of the stroke with the air pressure using the negative air chamber. The larger air cans are less progressive at the end of the stoke then the smaller ones. Most air can systems provide ways to reduce this volume with bands, tokens or some sort of volume reducing spacer. This allows the air can spring rate to be adjusted to match the leverage of the linkage system, linear and regressive ending linkages require a smaller volume so adding volume helps compensate to match the spring rate needed. The issue is this is a approximation of a coil system so the beginning and end of the stroke never really feel right. The last bit of travel is extremely progressive and can never be used, think of it as a cushion to prevent bottoming. The middle of the travel will go from linear to a progressive feel as the pressure begins to ramp up producing a bouncy feel compared to coil systems. The beginning of the stroke will sometimes be overwhelmed and suck down to cause the sag to feel too soft. The goal of a proper damper is to provide a firm low speed feel that still opens up on small bumps, enough mid speed damping to prevent fork dive without a harsh medium bump feel and enough high speed damping to prevent bottoming while still able to blow-off on high speed square edged bumps. Most of todays dampers have a very firm shim stack with a high threshold to get them to begin to open. This is because the design is based around the pedal platform which needs a very high threshold to prevent unwanted movement in the beginning of the stroke. It also allows heavier riders to be accommodated with the mass production generic valving. Because of this firmer valving system they chose to provide a open or bypass mode to allow the oil to go around these shims. This effectively makes the damper feel softer but at the expense of not allowing low to mid speed damping to be created, i.e. its just a hole. Adding low speed compression helps the fork dive but at the expense of creating a very harsh feel when hitting bumps. Most riders end up with this compromise and settle for this as the best setting that sort of works. As a result of this softer open mode most experience a very soft midstroke, bottoming way too easily and end up adding tokens to prevent this, resulting in a very progressive unwanted feel again. Our damper modifications and cartridge systems provide the necessary damping circuits for us to valve and set up you suspension properly. In the case of the forks we replace the stock damper with our open bath cartridge. For the rear shocks we have redesigned the internal adjustment systems which allows us to revalve the main piston to properly match your linkage leverage. Each of these systems are set up and designed around descending rather than pedaling, this allows for the main valving systems to meter the damping properly providing a firmer more controlled descent will still maintaining that plush feel. Essentially you can dial in the desired compression damping without that harsh feel, this will provide you with the proper balance between trail and descending. The traditional single spring systems found in Fox 40, Van 36 forks, Boxxer, older Lyriks and Marzocchi 888 forks weighed more than air forks and saved complexity over two springs and two dampers but produced a very linear spring rate and required some sort of end of stroke ramp up or anti bottoming system. Push and Vorsprung are selling this style. We decided to sell a dual spring system to save a bit of weight and create equal support with both legs but still required an abs system to prevent bottoming. All these systems require the purchase of the exact spring rate to support your weight and in most cases the choice of springs force you to choose slightly stiffer of softer than you might like. The ramp-up could be a bit abrupt at the end depending on the damper and devices used with each system. Our dual spring uses the air over oil in the damper side (about 80 psi) ramp up and and a hydraulic abs end of stroke bottoming resistance. The hybrid system creates a dual spring system for close to equal support on each stanchion and saves weight and complexity over the above systems. It provides a coil like feel in the first half of the travel and the air side creates the progression needed at a much lower pressure and thus less stiction. It allows for a wider spring rate adjustment by changing air pressure and ramp rate. The damper side spring allows for physical preload to set sag properly and providing a very smooth air ramp up with the air over oil. The best part of all is it is the lowest cost option while being the most versatile of all of the systems. How can we better make a coil fork even better! A little history as to how this happened: The original or traditional coil forks were designed for for MX and the early MTB forks with a damper and spring in each side, filled about 2/3’s with oil. This allowed the fork to create a coil spring like feel for the first half of the travel. The air space above the oil is compressed which produces an additional spring force in the last half of the travel. This additional air spring effect does two things, it allows the selected coil spring rate to be much softer because the air supplements and increases the spring rate and the ramp up or progression can still be controlled by the air volume compression by changing the oil height. MTB forks eliminated one damper to save weight and reduce the cost to produce over the past 20 years and used a single long over rated spring with no oil in the coil leg. This led to an air spring version that emulates a coil to further reduce the weight. This is essentially is where we are now with your typical air spring system single damper front fork. Our hybrid coil conversion brings back the ideal coil/air spring system without the added weight of traditional spring/oil filled fork. The air side is still used to create the additional spring rate and ramp rate at a much lower pressure. We use our open bath damper with a lighter and shorter coil spring on top of it. The air spring side remains unchanged and creates the additional spring rate. The air side now uses about 1/3 the pressure that you currently used to create the additional spring rate which can be adjusted to support your weight and ramp up desired. This hybrid system works in conjunction with our open bath custom valved damper with our exclusive midvalve and high speed blow off system (FvAT/HSB). Our damper creates a very supportive compression system that prevents fork dive and still feels plush on small bumps. This midvalve system and base valve will still blow off to prevent deep square edged harshness without bottoming. The damper and hybrid spring are $499 and $189 respectively. The spring weighs about 180-250 grams and the open bath damper weighs within 100 grams of the latest sealed OEM dampers. The optional FvAT/HSB is $89. Available for Rockshox Boxxer, Fox 40, Fox 49, Bomber 58, BomberZ1 (160/150/140), Fox 36 - (160/150/140), Yari/Lyrik 160/150/140(riders under 200 lbs).

|

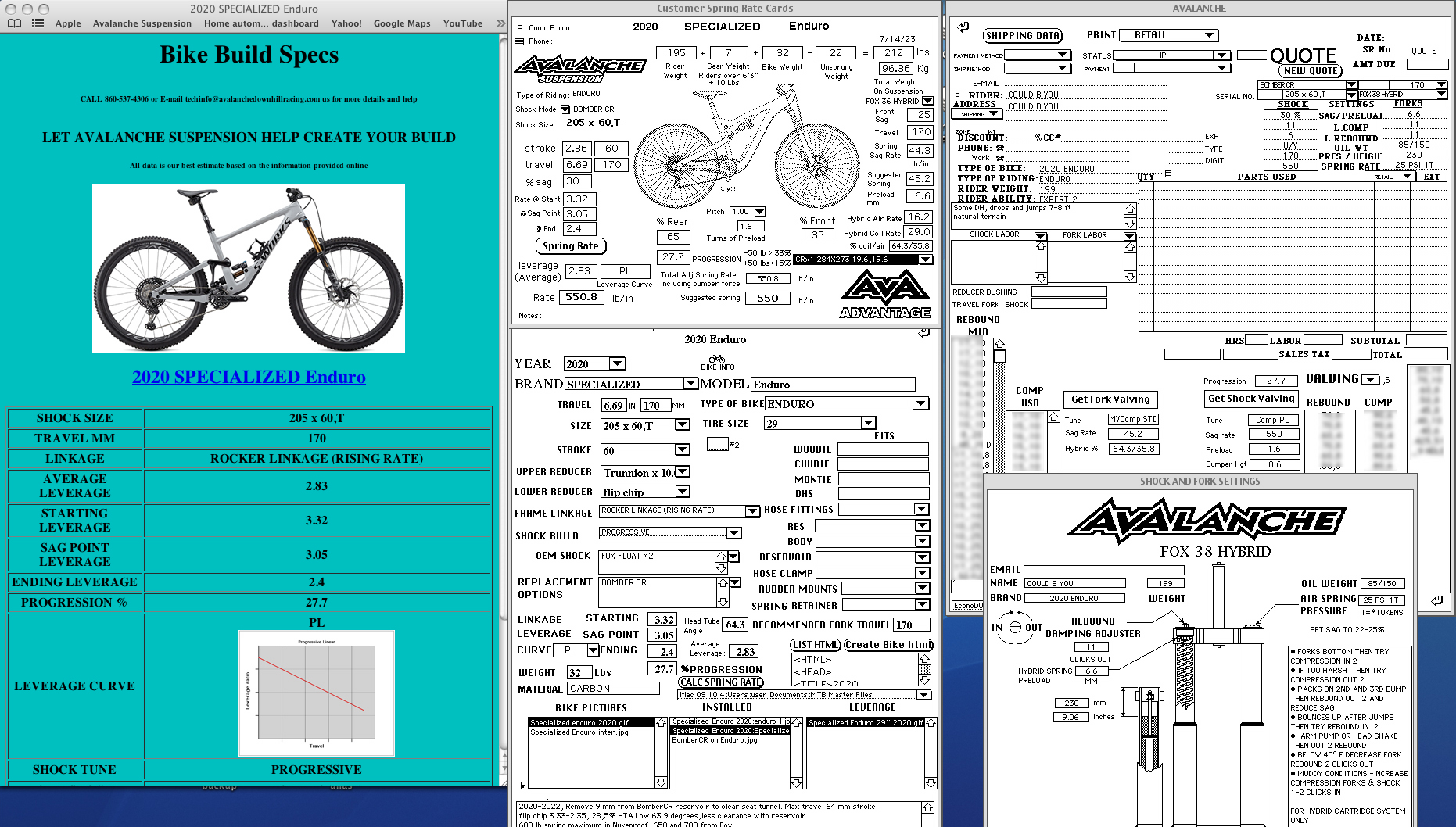

Includes New Interactive Set-Up Chart

What is involved

in getting your suspension modified, tuned and setup when you place

an order, call or e-mail us? |

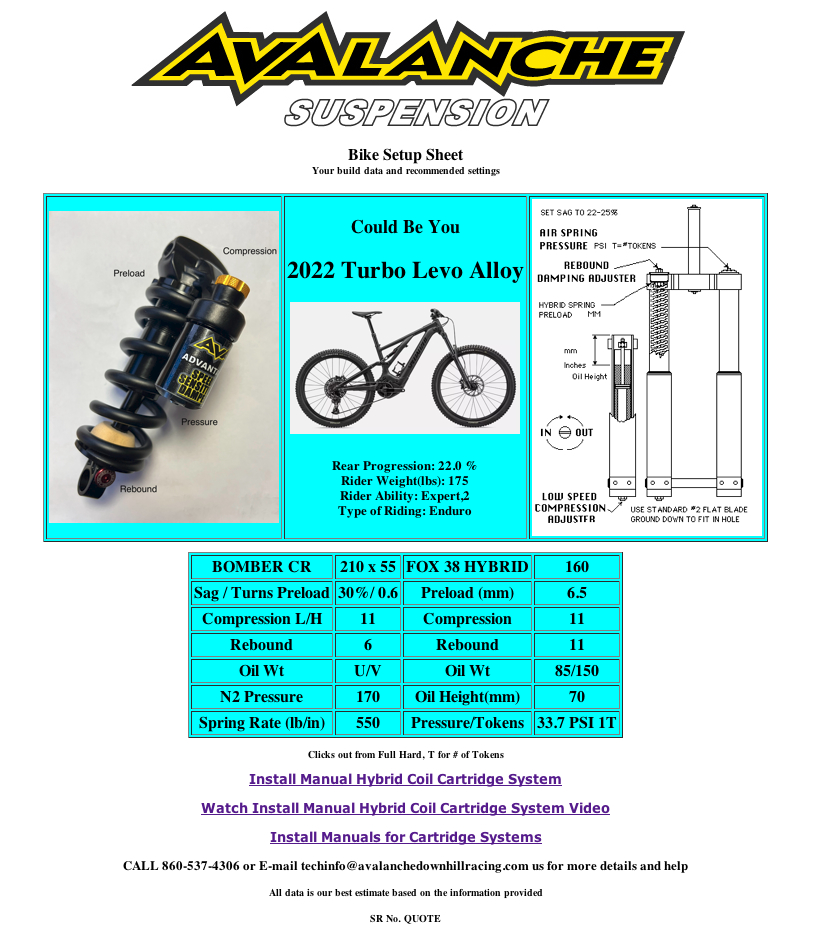

| 1. When you call or e-mail us we will recommend the best shock and fork choice and create a worksheet for your bike model and rider info. 2. Our Expert System looks up and cross references in our database and calculates the spring rates (air shocks where needed) needed for your bikes leverage, travel and rider info. 3. Your custom modification parts and springs are selected from our inventory and added to the customer data sheet. 4. We send quotes for our recommendations along with the customer data sheet with bike specifications, and based on the customers choices generate an invoice for down payment to get the customer in our queue. 5. Our AI generated valving and tuning data is determined by comparing our previous customer data, database and test data for that bike to recommend the best valving and setup data choice, which we tailor to the specific requirements provided and discuss the final choice with the customer. 6. Our office manager will estimate based on our current backlog and work with you as to when your suspension can be shipped to us to begin the work. 7. Follow up emails are incorporated into the work orders to keep any changes up to date on your work sheet, as changes are generally easy to incorporate. 8. Your work is generally completed within the week it is sent to us, any issues found or that might arise will be discussed with the customer and can be corrected if needed. 9. The completed work is shipped with the components set to the starting recommended settings along with a setup sheet for your records. 10. Follow up calls and e-mails from the customer to help with installation or setup are handled by personal phone calls when possible and e-mail if calling is inconvenient. |

techinfo@avalanchedownhillracing.com