Fox DHX 5.0/4.0 Coil Speed Sensitive DamperAdjuster Mods

![]()

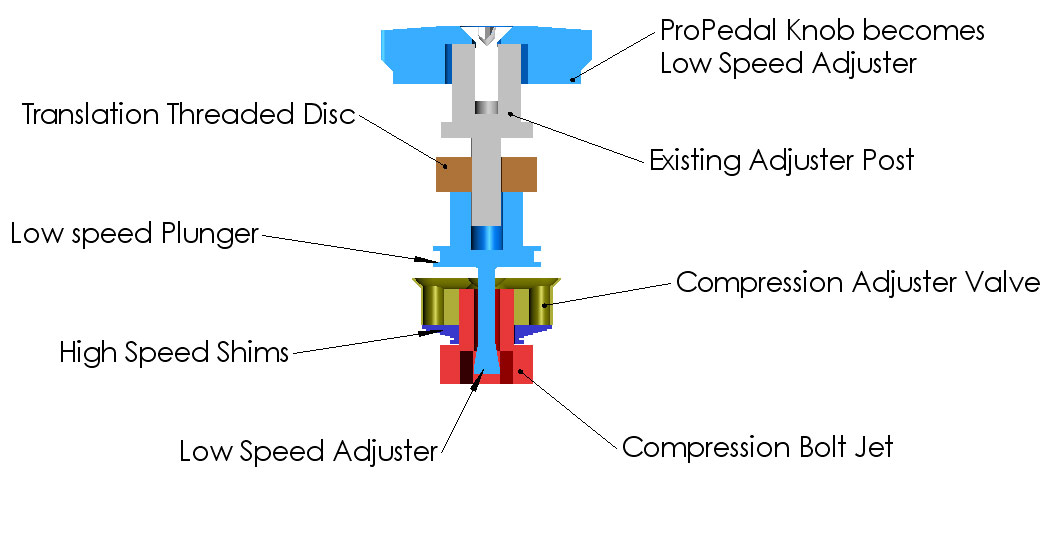

Replaces ProPedal Adjuster with a low speed compression

adjuster and custom valved high speed piston system in the existing Fox piggyback

housing.

This conversion complements the revalved main piston to completely convert

the DHX/VanRC to a true speed sensitive damper.

Technical Discussion |

|

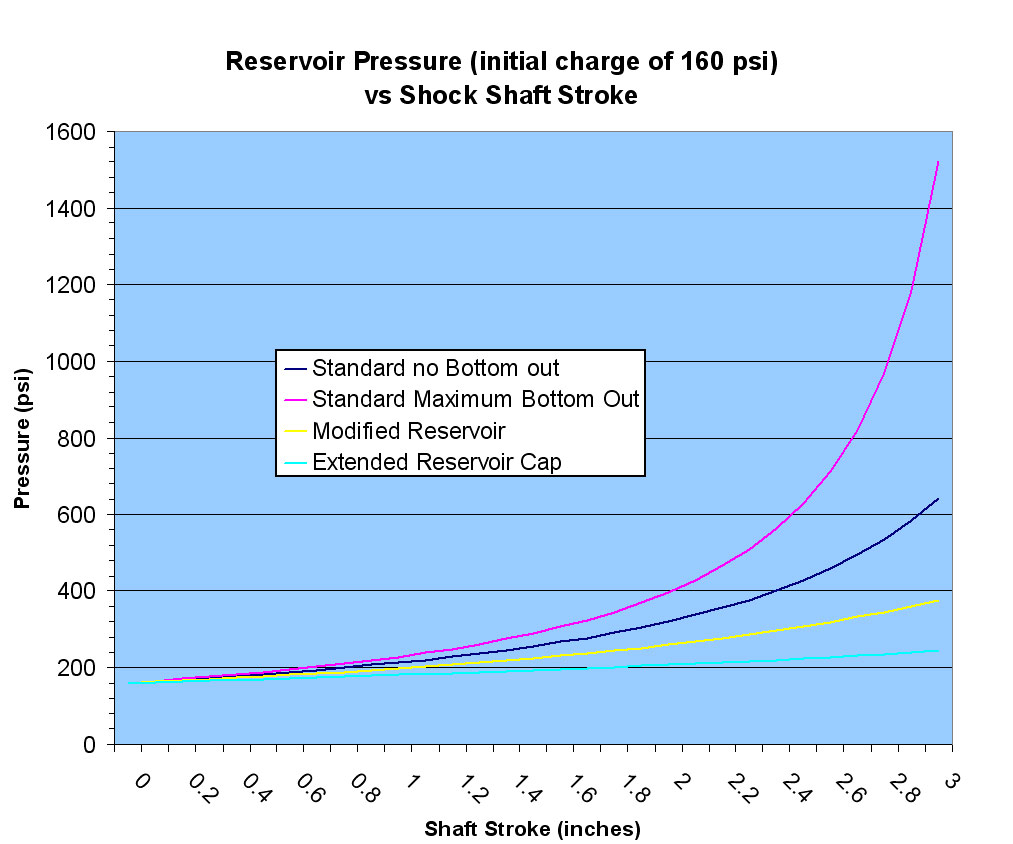

Why change out Propedal valve in the DHX?....The design of the Propedal creates a great position sensitive shock. As the pressure in the shock goes up the propedal valve gets harder to open, this creates more compression damping. The pressure can be increased 3 ways, first my adding more air pressure to the schrader valve, second as the shaft compresses, the displaced oil compresses the reservoir floating piston down, which drives up the pressure in the reservoir, and lastly the chamber compensation bottom out can be dialed in to decrease the reservoir volume and thus cause the pressure to be driven up even faster as the shaft compresses. The Propedal adjuster allows the rider to compensate for the pressure on the valve by applying opposite spring pressure to the valve reducing the force required to overcome this internal pressure and allowing the valve to blow-off more easily. So this all sounds great but in a real world where courses and terrain are not perfectly smooth and void of square edge holes, this is where the Propedal system fails to allow the valve to blow-off. When the shock hits square edge bumps deep in the stroke the valve becomes harder to blow-off and is actually getting firmer the deeper it gets in the travel (Position sensitive damper). This is why the Speed Sensitive Damper (SSD) is preferred, as the shaft speed needs to increase the compression adjustment valve needs to blow-off when the bumps become square edged or what we call high speed hits. This creates the need for the conversion and replacement of the propedal system to a shimmed ported valve. Since the shim stiffness is not affected by the build up of pressure in the reservoir, the shims can create damping at low and medium speed compression hits and be valved to blow-off when higher shaft speeds occur thus allowing the damper to smoothly resist the square edged hits. Because the main piston was valved for a very progressive position sensitive Propedal valve we can now revalve the main piston to contribute to the compression circuit and due to the decreased ramp up in the overall spring rate of the damper, the rebound stack can be revalved to be more linear . The main piston can now control it's 70% share of the compression damping giving us many more tuning options for rider set-ups. Rebound can be tuned to be more reactive on small bumps and provide lift where needed while preventing that pogo stick feel. Increased reservoir volume reduces pressure build up deep in the stroke, reducing heat build-up and increased oil and seal life. Optional reservoir volume systems available as shown below: |

|

|

|

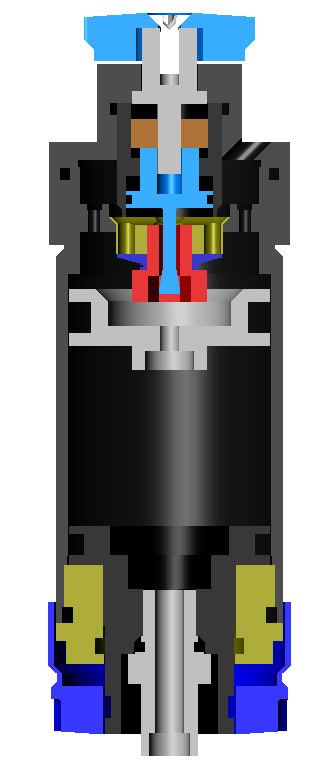

| Unmodified Bottom-Out Control .78 max, 0.66 min cubic inches Standard (3 inch Stroke) use with regressive to linear set-ups |

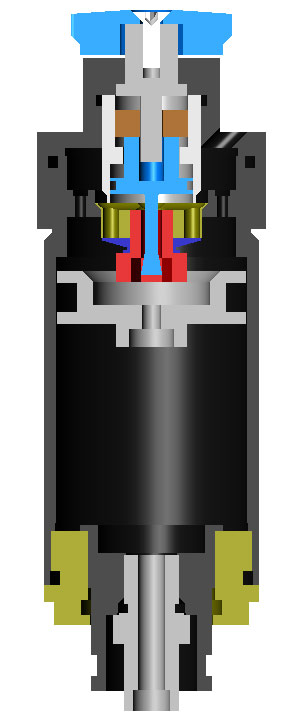

Modified Reservoir Volume 1.0 cubic inches 30% increase (1.3 times) use with linear to progressive set-ups |

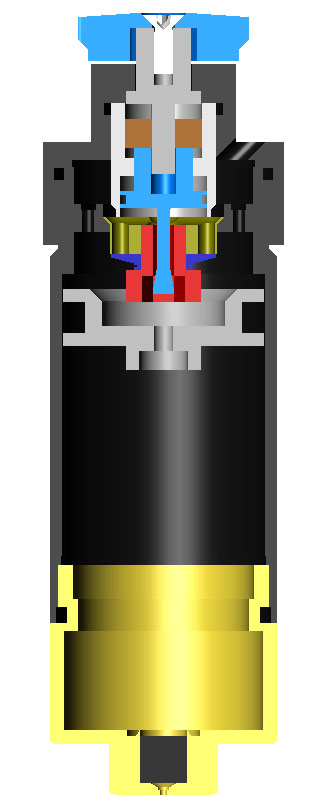

Extended Reservoir Volume 1.7 cubic inches 120% increase (2.2 times) use with progressive to rising rate set-ups |

For a 1/2 inch diameter shaft, 1500 psi equals 294 lbs extra spring

force

in other words for a 300 lb/in spring at 3 inches of stroke, the spring rate

would increase to 400 lb/in.

|

What does all this mean? For regressive set-ups it might be good to add a bit more compressive force at the end of the stroke, but this does not come at no cost, as the shock compresses rapidly the reservoir also heats up and causes the nitrogen pressure to even further increase. Even though the propedal valve that was activated by this pressure increase has been removed, the seals, the o-rings and the oil have to deal with much higher pressures then needed. Typical initial nitrogen charge of 160 psi is enough to prevent internal cavitation and allow the shock to have proper damping. So generally for most shock set-ups it is advantageous to keep the pressure as low as needed and prevent the pressure from ramping up as the shock is compressed. The larger the reservoir the less pressure increase during full compression, this pressure effects the midstroke harshness for rising rate linkages. Also the longer the run the hotter the shock gets, and with small reservoir volumes this could double the pressure in the shock at the beginning of the stroke and make it feel topped out or over preloaded. Regressive linkages like the "Sunday" only benefit from the bottom-out unmodifed original reservoir. Most frames will need more nitrogen volume and will require the modified reservoir. The DHX 4.0 volume has a preset Bottom-out feature as well so the volume needs to be modified, but will also except the extended reservoir cap. High rising rate frames and aggressive extended downhill runs on linear and progressive linkages will need the extended reservoir. |

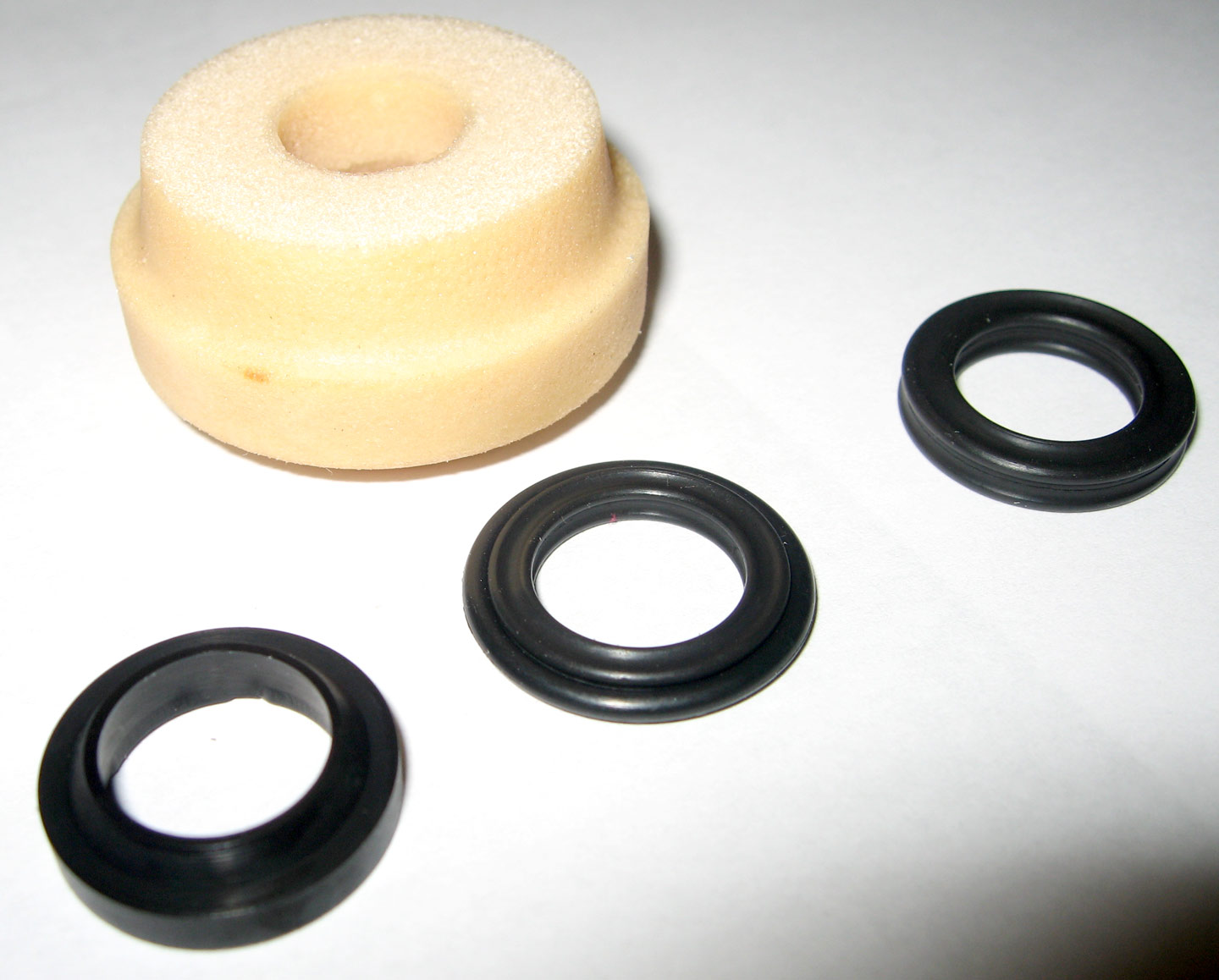

Stock DHX Bumper, Dust Seal and Oil Seal

AVA Advantage Shape Factor Bottom-Out Bumper, HardCoat Friendly Dust Scraper, water and mud seal, and Viton Low friction Oil Seal

Assembled and revalved Main shaft piston, seal head and Shape Factor Bottom-Out Bumper

Specifications:

16 mm Speed Sensitive flow controlled 4 port Compression Valve

15 Clicks of Low Speed Compression, uses exiting Propedal knob as new low

speed adjuster

* VanRC has Modified High Speed Adjuster Valving with wider range 22 click

low speed adjuster

Revalvable 6 mm ID shims

High speed adjustment - Internal Shim Stack

Nitrogen charged to 160 psi, fixed (i.e. no need for adjustment now)

Retains bottom out system to aid with pressure ramp up needed for regressive

linkage frames

Installs directly into the DHX housing...which preserves same top housing

and adjuster knob for fit compatability of existing frame applications

Low friction main shaft Seal

Shape Factor Bottom-out Bumper, optional

Modified Reservoir Volume , optional

Extended Reservoir rubber plug cap for maximum volume, optional

techinfo@avalanchedownhillracing.com